New Product Foam Concrete Blocks Amarna Consult Ltd.

Amazing process of making foam concrete blocks | production of foam blocks with subtitles Bb Amazing Skills 11.2K subscribers Join Subscribe Subscribed 8.8K 1.3M views 5 months ago.

Rectangular Foam Concrete Block, Size 625 x 250 x 115 mm, Rs 2250 /cubic meter ID 17313359212

This 7/32″ thick x 1-1/2″ wide corner bracket was engineered to add more strength/support to the block because it connects the inner/outer modified Expanded Polystyrene (EPS) foam panels together and is designed to eliminate blow-outs during the concrete pour.

Foam Construction Cinder Blocks Becker's School Supplies

$ 29 99 each SELECT STORE & BUY LiteForm® 8" Straight Block Insulated Concrete Form Model Number: LF08 Menards ® SKU: 1638100 Menards® Low Price! $ 29 99 each SELECT STORE & BUY Patented folding ties provide for easy transport and less job site space. Includes 8 ties per form.

Foam concrete manufacturing Foam concrete machines

Green Building Technical Resources Gallery Training Find a Dealer Meet Our Award Winning ICF Block Amvic™ Insulated Concrete Forms (ICF) are a stay in place, 5-in-1 concrete forming system incorporating structure, insulation, an air/vapor barrier and a finish attachment.

Molds for the production of foamed concrete foam blocks series Robus Buy on

The Fox Blocks insulating concrete forms are the best wall system to be used in a building envelope for obtaining a high Energy Star rating. The Fox Blocks steady-state R-Value is R-23. This R-value is the same for below grade, above grade, residential, commercial projects. The R-Value is the same for any wall thickness.

Aerated concrete, foam сoncrete block making machine ARK005 YouTube

These fully assembled blocks feature rugged 2 3/4" foam panels for a typical wall assembly R-value of R25.. high performance concrete construction to be. 6 in 1 Construction. Six construction steps in one simple package! Building with Logix helps save valuable time on the job site, helping you reduce labor costs during your build.

NewRuleFX Lightweight Foam Replica Cement Cinder Block Prop Effect Amazon Price Tracker Pricepulse

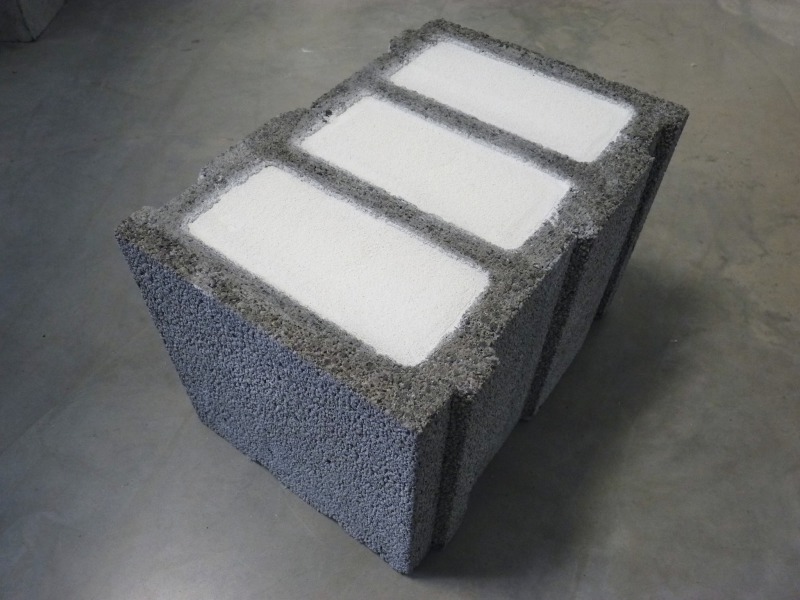

ICF Solutions Insulating Concrete Forms, (ICF's) are used to construct concrete based buildings. The molded foam blocks replace traditional forms and, since they remain in place after the pour, they provide excellent insulation and sound dampening qualities.

Rectangle Foam Concrete Block, Size (Inches) 24 X 8 X 4 Inch at Rs 3100/cubic meter in Belgaum

BuildBlock Insulated Concrete Forms (ICFs) are a building system that uses interlocking EPS foam blocks to create a formwork for reinforced concrete walls. The foam blocks are designed to interlock, creating a tight and secure formwork for the concrete.. Open Web Design for efficient concrete flow and half-height block support. Extra Heavy.

NewRuleFX Lightweight Foam Replica Cement Cinder Block Prop Effect Amazon Price Tracker Pricepulse

Foam concrete A cylinder of foam concrete. Foam concrete, also known as Lightweight Cellular Concrete (LCC) and Low Density Cellular Concrete (LDCC), and by other names, is defined as a cement -based slurry, with a minimum of 20% (per volume) foam entrained into the plastic mortar. [1]

Rectangular 4 Inch Foam Concrete Block at best price in Bengaluru ID 20316632312

The built-in anti-lift technology, locking all blocks down by concrete pressure on it. This eliminates the need to tie or lock down each row, making your installation faster. Design Flexibility SuperForm ICFs are designed with maximum design freedom with a 1″ repeating cut lines.

Foam Insulation Concrete Block Foam Insulation TipsFoam Insulation Tips

What Are Insulated Concrete Forms (ICF)? Insulated concrete formwork, commonly known as ICF, is a construction method used in home building that utilizes styrofoam foundation forms to create a strong and well-insulated structure. It's an alternative to traditional wood-frame housing.

Cellular Lightweight Concrete (CLC) or Foam Concrete SESBE

ICF Building Blocks Feature. The ICF (insulating concrete forms) building block system uses EPS (Expanded Polystyrene) foam blocks that act as hollow forms into which ready-mix concrete is poured to build reinforced concrete walls. The panels of both the ICF block and panel systems typically have a length of 48" with heights ranging from 12.

Source Top Quality Manual Foam Concrete Hollow Block Mold For CLC Blocks on

Foam block construction is known for its faster construction process compared to traditional methods. The interlocking foam blocks are quick and easy to assemble, eliminating the need for extensive formwork systems. The speed of construction can lead to cost savings and shortened project timelines.

Foam concrete blocks YouTube

1 Prepare the materials. Download Article Ensure that you have all the correct materials. The needed supplies include sand, water, block molds, gloves, and safety glasses. Do not worry if you do not have a cement mixer, as it can be substituted by a wheelbarrow. 2 Calculate the amount of materials you'll need. Download Article

Concrete Plant Precast Technology

From the mixing of raw materials to the final product, this video provides a detailed look at how foam concrete blocks are made. Witness the precision and ca.

Concrete is being poured into the wall forms made by the rigid foam insulated concrete form

BuildBlock webs provide embedded studs anchored to the concrete 1/2″ below the block surface to prevent thermal bridging and strong secure attachments. Patented High-Density Hard Attachment Points Each web has two high-density 450lb.+ hard attachment points spaced every 8″ vertically to attached heavy cabinetry, bracing, and more directly to the ICF.